Key Takeaways

- Role and Importance: Assemblers are crucial in manufacturing, responsible for assembling and ensuring the functionality of products, impacting overall production quality.

- Key Responsibilities: Daily tasks include assembling components, conducting quality inspections, documenting processes, and collaborating with team members for efficiency.

- Essential Skills: Success as an assembler demands attention to detail, problem-solving abilities, mechanical aptitude, and effective communication skills.

- Work Environment: Assemblers typically work in manufacturing settings, facing varied physical demands and potentially hazardous materials, requiring appropriate safety measures.

- Salary and Opportunities: The median annual wage for assemblers is around $39,720, with steady demand projected in various sectors, highlighting the importance of a skilled workforce.

- Industry Variance: Different industries, such as technology and automotive, present unique assembly challenges, making industry-specific training and expertise vital for operational success.

If you’re considering a career as an assembler, you’re stepping into a vital role in the manufacturing process. Assemblers play a key part in bringing products to life, ensuring that components fit together seamlessly and function as intended. This job not only requires attention to detail but also a solid understanding of tools and machinery.

In this article, you’ll discover what an assembler’s job entails, from the specific skills needed to the daily tasks involved. Whether you’re just starting out or looking to enhance your knowledge, understanding the assembler job description can help you navigate this dynamic field. Get ready to explore the ins and outs of this essential profession and see how you can thrive in it.

Overview of Assembler Job Description

Assemblers play a crucial role in small businesses, ensuring products are built accurately and meet quality standards. As an assembler, your daily responsibilities include assembling components, testing products for functionality, and performing quality checks.

Key Responsibilities:

- Assemble products according to specifications and blueprints.

- Use hand tools, machinery, and equipment effectively.

- Conduct quality inspections to ensure compliance with standards.

- Document assembly processes and report any discrepancies.

- Collaborate with team members to improve production efficiency.

Essential Skills:

- Attention to detail for precise assembly tasks.

- Good problem-solving skills to address production challenges.

- Basic mechanical aptitude to understand tools and machinery.

- Effective communication skills to work with your team.

In small businesses, hiring skilled assemblers ensures smooth operations and product reliability. Consider the impact of well-trained employees in maintaining high production quality and meeting customer satisfaction.

Key Responsibilities of an Assembler

Assemblers play a vital role in small businesses by ensuring that products are assembled accurately and efficiently. Their contributions directly impact production quality and operational success.

Assembly Line Duties

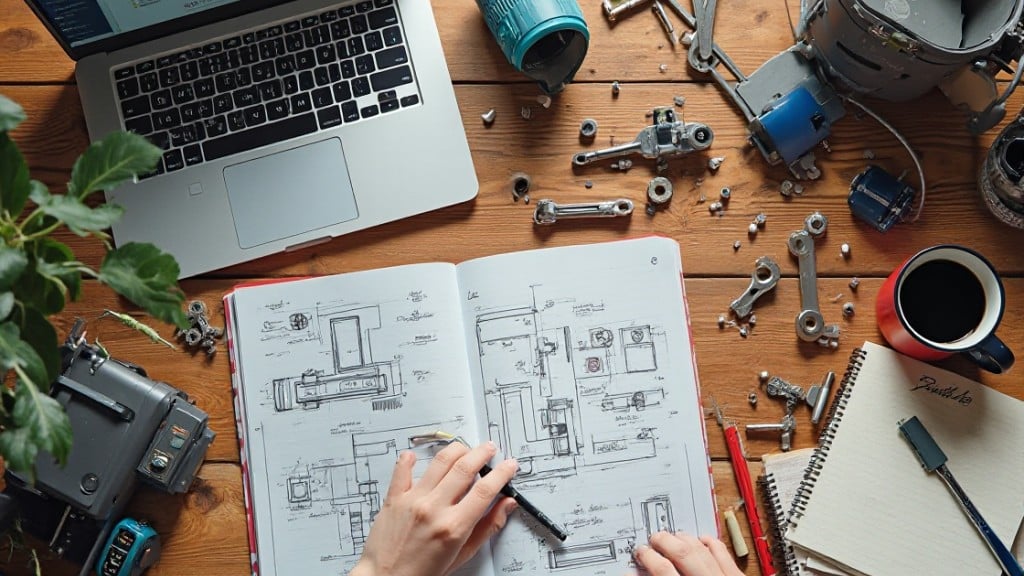

Assemblers fit, assemble, and fabricate components on the production line. You utilize hand tools and machinery to install parts, adhering strictly to specifications. By reviewing technical documents like blueprints and manuals, you ensure the correct assembly of various products. Collaborating with fellow assemblers on the production floor helps facilitate a smooth workflow and allows for immediate troubleshooting of assembly issues.

Quality Control Tasks

Quality control is central to the assembler’s role. You conduct thorough inspections of assembled products to verify proper functionality and visual standards. Documenting findings enhances the consistency and reliability of production outputs. If defects arise, taking corrective action quickly protects the integrity of your products.

Maintenance and Cleanliness

Maintaining a clean and organized workspace is essential. You prepare tools and materials specifically for the assembly process while ensuring that equipment remains in optimal condition. Regularly cleaning work areas prevents hazards and enhances efficiency. Upholding these standards also fosters a culture of accountability among employees, contributing positively to the overall work environment in your small business.

Required Skills and Qualifications

Assemblers play a crucial role in small businesses, requiring specific skills and qualifications to succeed in their positions. You’ll find that both technical and soft skills contribute significantly to the effectiveness of an assembler.

Technical Skills

- Blueprint Reading: You need the ability to interpret engineering blueprints. Understanding these documents is essential for assembling products accurately.

- Tool Proficiency: You should demonstrate expertise in using various tools for making or repairing parts. Familiarity with hand tools and machinery enhances assembly efficiency.

- Technical Document Interpretation: You must be capable of interpreting diagrams, schematics, and other written instructions. This skill guarantees that assembly processes align with specifications.

- Quality Control: You must identify defective items and manage them according to established procedures. Knowing how to troubleshoot problems as they arise is vital for maintaining production quality.

Soft Skills

- Attention to Detail: You must exhibit thoroughness in assembly tasks. Noticing small discrepancies can prevent larger issues down the line and supports the production of high-quality products.

- Problem-Solving Abilities: You need to think critically when faced with challenges. Effective problem-solving ensures that assembly remains on track and meets deadlines.

- Communication Skills: You should possess clear communication skills, allowing for effective collaboration with team members. Working well with others improves overall operational efficiency in a small business.

- Organizational Skills: You must maintain a clean and tidy workspace. An organized environment fosters productivity and enhances safety for all employees.

Work Environment and Conditions

Assemblers often operate in a dynamic work environment, typically found in factory settings, manufacturing, and production facilities. Specific conditions may vary, including work posture, noise levels, and exposure to materials.

Typical Industries

Assemblers contribute to a range of industries, which include:

- Technology

- Health care

- Aerospace

- Textiles

- Automotive

- Aircraft manufacturing

Each industry presents unique assembly challenges and standards, emphasizing the need for skilled assemblers to maintain product quality. For small businesses, ensuring that the workforce adapts to industry-specific demands is crucial for your operational success.

Physical Demands

Assemblers face various physical demands that can influence health and safety. They may alternate between sitting and standing, often climbing ladders to complete tasks. Exposure to potentially hazardous materials, such as chemicals and fiberglass, requires assemblers to wear personal protective equipment (PPE). The temperature in workplaces can fluctuate, necessitating appropriate clothing to ensure comfort. For small businesses, understanding these demands aids in effective staffing and promoting employee well-being.

Maintaining a safe and efficient work environment enhances productivity, directly impacting your business’s success.

Salary and Career Outlook

The median annual wage for assemblers and fabricators stands at $39,720 as of May 2023, translating to approximately $19.10 per hour. Salaries vary significantly depending on experience, location, and industry. For small business owners, understanding these figures is essential for budgeting and competitive staffing.

Market trends indicate steady demand for skilled assemblers in various sectors, including technology, healthcare, and automotive manufacturing. As industries grow, the need for capable employees increases, presenting opportunities for enhancement within your workforce.

In the hiring process, emphasize the importance of experience and skill set. For instance, employees with prior assembly experience may command higher salaries but can also contribute significantly to operational efficiency and product quality. Consider offering competitive wages to attract and retain talent, ensuring your small business maintains a skilled workforce that meets production demands.

Conclusion

Understanding the assembler job description is crucial for both employers and aspiring professionals. This role is foundational in maintaining product quality and operational success. By focusing on the essential skills and responsibilities outlined, you can better appreciate how assemblers contribute to various industries.

Whether you’re looking to hire or pursue a career in assembly, recognizing the importance of attention to detail and technical proficiency will set you apart. As the demand for skilled assemblers continues to grow, investing in training and competitive wages can enhance your workforce and boost productivity. Embrace the significance of this profession to ensure your business thrives in a competitive market.

Frequently Asked Questions

What is the role of an assembler in manufacturing?

Assemblers are responsible for fitting, assembling, and fabricating components on production lines. They ensure products are assembled accurately and function properly by using tools and machinery according to specifications.

What skills do assemblers need?

Assemblers require technical skills like blueprint reading and tool proficiency, along with soft skills such as attention to detail, problem-solving, and communication skills, to effectively work in a team and maintain quality.

What are the daily tasks of an assembler?

Daily tasks include assembling components, testing products for functionality, conducting quality inspections, documenting processes, and collaborating with team members to improve overall efficiency.

What industries employ assemblers?

Assemblers are essential across various industries, including automotive, aerospace, and aircraft manufacturing, each presenting unique challenges that require skilled professionals.What is the salary outlook for assemblers?

As of May 2023, the median annual wage for assemblers and fabricators is $39,720, or about $19.10 per hour. Salary varies based on experience, location, and industry.

Why is quality control important for assemblers?

Quality control is crucial for assemblers as it involves thorough inspections to identify defects, maintain product consistency, and ensure that assembled products meet industry standards and customer expectations.

What is the work environment like for assemblers?

Assemblers typically work in factory settings or production facilities, facing physical demands like alternating between sitting and standing, climbing ladders, and using personal protective equipment (PPE) for safety.

How can small businesses ensure they have skilled assemblers?

Small businesses can attract and retain skilled assemblers by offering competitive wages, emphasizing experience and skill set during the hiring process, and fostering a positive and organized work environment.

Image via Google Gemini